What Is Aluminum Foil?

Aluminum foil is a thin sheet. It is made from an aluminum alloy.

The alloy comprises 92-99 % aluminum. Aluminum foil is prepared in numerous widths and strengths for various applications.

The usual thickness of aluminum foil ranges between 0.00017-0.0059 inches.

Aluminum foil is widely used to produce thermal insulation for the construction industry, electrical coils for transformers, insulation for storage tanks, capacitors for radios and televisions, decorative products, and packaging.

The extensive applicability of Commercial aluminum foil is due to its numerous advantages. Aluminum foil is low-cost, non-toxic, durable, and greaseproof. It offers outstanding electrical and non-magnetic shielding. Additionally, aluminum foil can resist chemical attacks.

Aluminum Foil

History of Aluminum Foil

The tinfoil was extensively used before the discovery of aluminum foil. In 1910 Dr. Lauber, Neher & Cie firstly built the aluminum foil rolling plant in Emmishofen, Switzerland.

In 1911, Bern-based Tobler started packaging its chocolate bars in aluminum foil. In 1913 aluminum foil was first used in the United States to package candy bars and gum.

How Is Aluminum Foil Made?

Raw Materials: (Aluminum Foil Composition)

Aluminum is considered one of the most abundant elements found on the earth’s surface. Aluminum makes up above 8% of the earth’s crust.

Though, aluminum does not occur in its pure and metallic form. It mainly exists as hydrated aluminum oxide combined with silica, Titania, and iron oxide.

The raw material used for manufacturing aluminum foil is aluminum (Bauxite). Bauxite is the most important aluminum ore. To manufacture foil, pure aluminum is extracted from the bauxite.

Manufacturing Process

Extraction of pure aluminum foil from bauxite is completed in two processes, i.e., refining and smelting. Later extracted aluminum metal is rolled for making foil.

Refining — Bayer Process

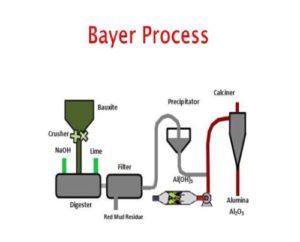

The Bayer process is employed for refining bauxite that comprises four steps.

Digestion: In this process, the combination of sodium hydroxide, heat, and pressure is employed to break the ore into a saturated solution of sodium aluminate and insoluble contaminants.

Clarification: Cloth filters trap the contaminants from the solution, which are then disposed of. After filtration, the residual solution is shifted to a cooling tower.

Precipitation: Deville method is used in this stage. The fluid is seeded with crystals of hydrated aluminum to support the production of aluminum particles.

At the end of this step, the large clumps of aluminum hydrate start to form. These are primarily filtered out and then rinsed.

Calcination: The Aluminum hydrate is exposed to high temperatures. As a result, the fine white powder (aluminum oxide) residue is obtained.

Bayer Process

Smelting

Smelting is the next step in extracting pure and metallic aluminum from bauxite. It separates the aluminum-oxygen compound (alumina) produced by the Bayer process.

This step uses an electrolytic method invented by Charles Hall and Paul-Louis-Toussaint Héroult.

Firstly the alumina is dissolved in a smelting cell. This smelting cell is a deep steel mold lined with carbon and filled with a heated liquid conductor that mainly comprises the aluminum compound cryolite.

Then an electric current is passed through the cryolite that causes a crust to form above the peak of the alumina melt.

After the stirring process, pure molten aluminum is formed on the bottom of the smelting cell. The purified aluminum that is still in molten form is then drawn from the smelting cells, transported into crucibles, and emptied into furnaces.

During this procedure, aluminum alloy can be prepared y adding other elements. The molten aluminum is then poured into direct chill casting devices; after being annealed, the mixture is treated with heat to improve workability.

Rolling Foil

After forming foil stock, the machines condense it in thickness to prepare the foil. For this purpose, a rolling mill is used. The material is passed several times through metal rolls termed work rolls in this mill.

When the aluminum sheets pass through the rolls, they are compressed thinner and extruded by the gap among the rolls. Lubricants are added to assist the rolling procedure. The aluminum sporadically should be annealed during the rolling process to sustain its workability.

The foil sheets are trimmed with razor-like knives fitted on the rolling mill. For certain converting and fabricating operations, foil webs that have been wrecked during rolling should be connected back together or spliced.

Foil Rolling

Finishing Processes

The rolled foil can be coated with various materials like polymers and resins for decorative, heat-sealing, or protective purposes. The foil can be laminated to paperboards, papers, and plastic films.

The aluminum foils can be colored. The colored aluminum foil usually includes blue aluminum foil and gold aluminum foil.

The foil can also be cut, printed, embossed, formed into any shape, slit into strips, sheeted, anodized and etched. Once the aluminum foil roll is in its final form, it is packaged and shipped to the consumers.

What Are the Uses of Aluminum Foil?

You can use aluminum foil for various purposes. Some of its uses are:

Aluminum Foils Use

It is used for:

- Food packaging

- Lining cabinets and drawers

- Polishing silverware

- Cleaning the grill

- Cooking and Baking (to protect pie crust)

- Credit card Concealing

- Scrubbing dishes

- Softening hard sugar

- Making a funnel

- Scaring away birds

- Electromagnetic shielding

- Laundry

- Cosmetics

What Are the Advantages of Packaging with Aluminum Foil?

- Aluminum foil is most widely used for packing food as it hinders the contamination of food items by bacteria. There are various advantages of using aluminum foil for packing. Some benefits are described here:

- Aluminum foils seal the odor of packaged food items. If you put food in a fridge packaged with thick aluminum foil, you will not have to deal with the unbearable smell.

- Foil wrapping is perfect for anybody preserving food that will require reheating soon. Due to the ability of aluminum foil to endure high temperatures, it allows reheating of packaged food in the oven or microwave.

- Aluminum foil is highly resistant to light, bacteria, moisture, and gases. Due to these properties, the food packaged with aluminum foil lasts longer than the food wrapped in plastic.

- The aluminum foil protects the packaged food item from contact with germs due to its bacterial resistance.

Can You Recycle Aluminum Foil?

Aluminum foil is a biodegradable product. Aluminum foil and trays are 100% recyclable. For recycling your aluminum foil and trays, you must give them a fast rinse after usage. After that, place them straight in the curbside recycling container.

The designated workers will take your aluminum foil to a materials recovery facility from this container.

This facility recycles aluminum foils and trays. The aluminum recycling stream is considered one of the most effective streams in recycling. After recycling, this aluminum foil and tray can be reused as a new tray or foil.

Conclusion:

If you are looking for recyclable foil for food packaging, aluminum foil is the best option. The accuracy of the manufacturing process of aluminum foil ensures its quality. You will get an aluminum foil with various thicknesses in the market.

You can get high-quality aluminum foil from Kingchuan Company. The team members of this company strictly observe each step of the manufacturing process to ensure the best quality aluminum foil for its customers.