Qingdao Kingchuan – The Most Named BOPP Glossy Film Supplier in China

It all started in 1992. Since then, Qingdao Kingchuan Yuanrong International Trading Co., Ltd. has manufactured and supplied high-grade plastic films domestically and internationally.

Kingchuan is a trading company that has six branches in the mainland of China. These branches are located in Jining, Qingdao, Jinan, Zhengzhou, and Wuhan.

We have contracts and partnerships with the leading plastic film manufacturers worldwide. Kingchuan has relations with reputed organizations that help us to inspect the quality, technology, and durability of the products we serve.

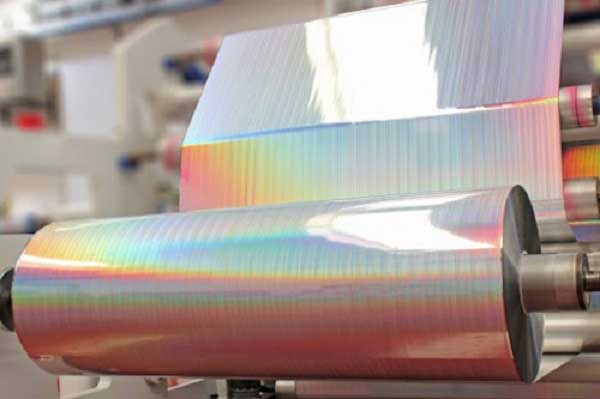

Moreover, Kingchuan ensures the product quality before supplying it to our valuable customers. We offer you abundant product categories like BOPP films, BOPET films, BOPA films, CPP films, PE films, PVDC coatings, and aluminum foils.

These glossy plastic films have a massive demand in the packaging industry. Kingchuan serves industries like food, pharmaceuticals, medical, and packaging.

Wholesale Bopp Glossy Film in Bulk

Except for Bopp plain films, Kingchuan also deals with some functional products like cling films, stretch films, and shrink films. You can get the products as per your business requirement. We give you the flexibility to wholesale in bulk or small MOQs.

Kingchuan has a well-established warehouse and inventory system. We keep abundant supplies in our warehouse so that you can get your orders on time.

Furthermore, 125+ employees work effortlessly, round the clock, to fulfill your demands. You can also get your custom-made plastic film solutions at Kingchuan.

Kingchuan not only provides you with top-notch products at competitive prices but also offers impressive promotional deals. Our happy and stable customers worldwide enjoy discounted prices on bulk orders.

In short, you can trust Kingchuan’s products and services because we survive for your satisfaction!