Get Connected with the World’s Best Heat Sealable Polyester Film Distributors

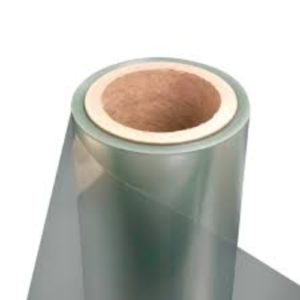

Qingdao Kingchuan is considered one of China’s leading flexible polyethylene coated PET heat sealable packaging film manufacturers and suppliers. The company provides you with a wide range of premium quality heat sealable oxygen barrier films. These high temperature heat sealable films are suitable for industrial and end-consumer packaging products.

We serve globally. With the help of our efficient and honest shipping partners, we ship orders in bulk or small MOQs not only to the domestic markets but all over the world. We ensure the availability of high quality heat sealable films 24/7.

You can contact us any time to place your order. You will get satisfactory results by using our heat sealing PET films.

Boost Your Market Value with Kingchuan’s Heat Sealable Laminate Films

You can enhance your market value by offering Kingchuan’s heat sealable films in the domestic market. Kingchuan believes in top-notch and high-quality products. It is the reason we manufacture and distribute products only from the world’s leading BOPET heat sealable film manufacturers.

We aim to develop a long-term relationship with our precious customers with honest and transparent dealing. We offer effective customer and after-sales services.

At Kingchuan, you will get high-quality films at competitive prices. We also offer barrier film heat sealable for sale. For more information, get connected with our efficient customer care team.

The Best Heat Sealable PET Film Sheets Supplier

Kingchuan is the best supplier of premium quality heat sealable films. We have advanced machinery for manufacturing these films. Our hard-working staff is trying their best to provide heat sealable film with the best features.

The heat sealable laminate films prepared by our company have excellent sealing performance and printability. These films are resistant to moisture, corrosion, and abrasion. We prepare eco-friendly packaging films.

These films are widely used for food packaging, metal lamination, lidding tubes, and bags and provide protective surfaces on glass fiber reinforced sheets.