The World’s No#1 Heat Transfer Film Manufacturer: Qingdao Kingchuan

We have carved a niche among the most trusted names in this business, engaged in contributing an inclusive range of heat press transfer films. Kingchuan was founded in 1992 and has been dedicated to manufacturing and developing high-quality transparent heat transfer film.

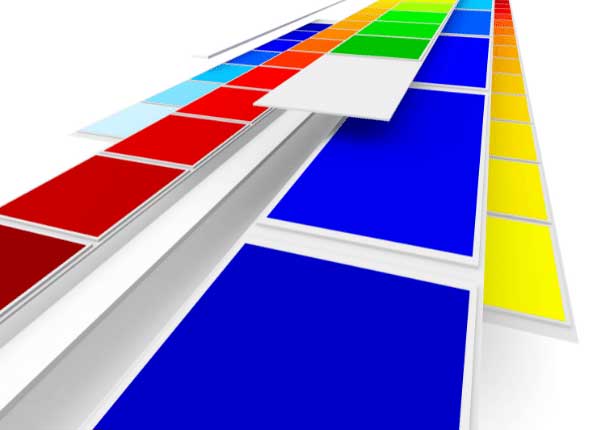

We aim to assist the clients and to develop sustainable operations to tend diversification expansion. Our company is equipped with the latest printing machines to accept multicolor requirements. We also have a high-quality automatic cutting machine which can offer a custom cutting service. Feel free to contact us for quotations.

Increase Your Business Circle by Kingchuan’s Printable Heat Transfer Film

Being a business owner, retailer, or wholesaler, you can increase your demand in the domestic market by Kingchuan’s transparent holographic heat transfer film. At Kingchuan, you can get polyester heat transfer film with your desired pattern and color. We also offer skateboard heat transfer film wholesale for our customers.

We insist on taking strict inspection management for offering our customers exceptional quality PVC heat transfer film. This Insistence decreases the subsequent processing loss and increases the product competition in the worldwide market. Our delivery time is short and prompt for satisfying the customer’s request, keeping the customer free of concern for the delay. We try to ensure that our customers contentedly recommend our heat transfer vinyl film to everyone.

The Best Heat Transfer Film Supplier

Kingchuan is regarded as the best supplier of heat transfer printing film for plastic products, heat transfer vinyl masking film, heat transfer film for semiconductors, heat transfer films for t-shirts, heat transfer film for skateboard, heat transfer printing film, laser-cut heat transfer film, and heat transfer film for hard surfaces.

You can also get your desired heat transfer film thickness at our company. We offer heat transfer film printing with multicolor, high resolution, and increased adhesive features. It is required for various products like stationery, commodity, electric application, toiletry, toy, and a plastic bucket.