Cosmetics quality and preservation are crucial. Customers expect beauty products to last, not contaminate, and not expire. Specialized packaging like BOPP heat-sealed film from China Bopp heat sealable film manufacturers can help achieve this. To preserve beauty, BOPP heat sealable film prevents cosmetic contamination and spoilage.

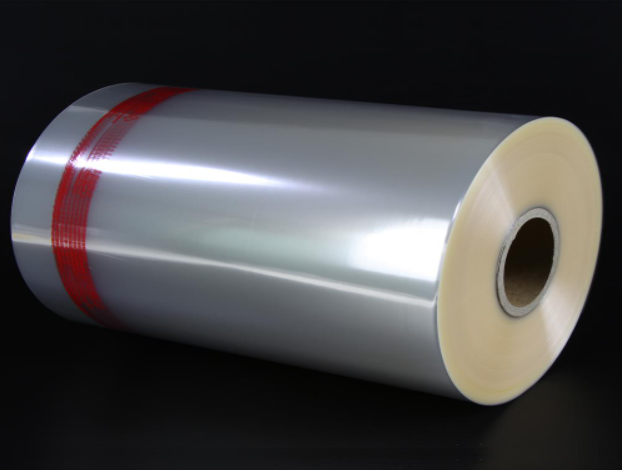

Learn about BOPP heat-sealing film:

Packaging material Barrier, heat sealing, and clarity are the strengths of BOPP heat sealable film. The biaxially oriented film made with polypropylene resin improves optical properties, strength, and flexibility. The food, pharmaceutical, and cosmetic industries use BOPP heat-sealable film. The versatile BOPP heat sealable film preserves products well.

How does BOPP heat sealable film affect cosmetic packaging?

- Barrier protection overall:

The BOPP heat sealable film from China Bopp heat sealable film suppliers protects cosmetics from moisture, oxygen, light, and other quality-reducing factors—the primary purpose of BOPP heat sealable film. Air and humidity degrade cosmetics, changing their texture, color, and efficacy. Cosmetics exposed to oxygen or moisture can do this. Protect cosmetic containers with BOPP heat-sealable film. Water and oxygen are blocked by this barrier, preserving product freshness and shelf life.

- Disturbance prevention methods:

Cosmetic microorganisms can harm consumers. BOPP heat-sealing film seals cosmetic packaging hermetically. Packaging dust, dirt, bacteria, and fungi decrease. This reassures customers that the product is safe to buy and eat, maintaining its hygiene.

- Product Authenticity Check:

Environment makes cosmetic formulations even more fragile. These formulations degrade active ingredients, fragrances, and pigments. BOPP heat sealable film prevents oxidation, evaporation, and leaching. BOPP heat sealable film maintains quality and performance by maintaining cosmetic formulation consistency.

- Tampering was evident:

Customer trust and brand reputation depend on genuine and safe cosmetics. BOPP heat-sealable film from China Bopp film suppliers makes many tamper-evident features possible: holographic seals, perforations, and tear strips. Visual clues help consumers spot tampered packaging. Product security and consumer confidence are improved by this measure, reducing the likelihood of counterfeit or adulterated cosmetics reaching the market.

Cosmetic packaging uses BOPP heat-sealable film:

- Construction Packaging:

Lip balms, face creams, and serums are often wrapped in BOPP heat-sealable film. Because BOPP film heat seals. Its excellent sealability makes this product a reliable and hygienic packaging solution that prevents leakage and contamination.

- Extra Packaging:

Pouches, sachets, and wrappers use BOPP heat-sealable film. Used in primary packaging and here. This secondary packaging keeps the product fresh and gives the manufacturer portability. Cosmetic companies using BOPP for secondary packaging reduce their environmental impact throughout the product lifecycle.

Advances in BOPP heat sealable film

The latest BOPP heat sealable film technology improves cosmetic packaging performance. Innovations caused these improvements. Recently, manufacturers have made ultra-thin films with better barrier properties. These manufacturers help create lightweight packaging that protects products while using less material. Modern printing and surface treatment can directly print decorative designs, branding, and product information onto film. Previously, film prevented this. Since then, product aesthetics and customer engagement have improved.

BOPP Heat Sealable Film has eco-friendly features:

- Recyclability:

One of the most significant environmental benefits of BOPP heat-sealable film is recycling. BOPP recycles better than other plastics. This facilitates a circular economy and environmental protection. Used BOPP can be recycled to make new products, saving resources and waste.

- Lightweights:

Lightweight BOPP heat sealable film reduces packaging weight. Cosmetic packaging is lighter, reducing transport and distribution emissions and energy use. This lowers cosmetic packaging’s carbon footprint.

- Optimizing Energy Use:

Packaging from BOPP heat-sealable film uses less energy than glass or metal. Because BOPP film heat seals. BOPP cosmetic packaging reduces pollution and greenhouse gas emissions due to energy efficiency. Thus, BOPP is greener.

- Safety and permanence:

BOPP heat sealable film safeguards cosmetics. Keeps contents fresh and consistent, reducing spoilage and damage for its barrier properties. BOPP packaging extends cosmetics’ shelf life, reducing waste and encouraging green consumption.

- Design adaptability, and execution functionalities:

BOPP heat sealable film is versatile for packaging. Because it supports multiple printing methods, it creates stunning designs. Brand visibility and customer appeal increase. Cosmetic brands that want to be sustainable use BOPP because it allows attractive packaging without compromising product eco-friendliness.

Case examples:

- A reputable cosmetics brand X:

X’s luxury skincare was wrapped in BOPP heat-sealable film. The film was added to the packaging. With its superior barrier and tamper-evident features, BOPP film helped the brand ensure product authenticity and integrity. This allowed the brand to look better and verify product authenticity. This reduced spoilage and tampering returns by increasing customer satisfaction and brand loyalty. More customers liked the brand.

- Eco-friendly cosmetics maker Y:

Environmentally conscious cosmetics company Y packages with BOPP heat sealable film. Recycling BOPP film and using eco-friendly inks and adhesives helped the company be ecologically friendly. Company Y used BOPP heat sealable film to maintain product quality and reduce its carbon footprint, making the beauty industry more environmentally friendly.

Trends and prospects:

Future cosmetic packaging may use BOPP heat-sealable film. Technological advances, consumer preferences, and regulatory changes may cause this. Cosmetics BOPP film will follow these trends:

- Sustainable packaging: Bio-based or recycled BOPP film from China Bopp film manufacturers is being developed due to consumer demand. For sustainability and recycling, packaging design is improving.

- Smart Packaging: RFID tags, NFC labels, and QR codes in BOPP heat sealable film improve traceability, authentication, and consumer engagement, promoting beauty industry transparency and trust. QR, NFC, and RFID are intelligent packaging technologies.

- Antimicrobial Properties: Antimicrobial BOPP films resist microorganism contamination. Consumer concerns about cosmetics safety and hygiene are addressed.

Some final thoughts:

BOPP heat sealable film preserves cosmetics from contamination and spoilage. Maintaining product beauty requires this. It is ideal for cosmetic packaging due to its excellent barrier properties, inability to be tampered with, and compatibility with many printing and decoration methods. BOPP heat sealable film should protect products and distinguish brands. The beauty industry innovates and prioritizes consumer safety and the environment.

BOPP heat sealable film is eco-friendly cosmetic packaging. This makes it appealing. Recyclability, lightweight, energy efficiency, durability, and design flexibility make the product environmentally friendly. Additionally, the cosmetics industry’s aesthetic and functional requirements are met. As consumer demand for eco-friendly packaging rises, the cosmetics industry uses BOPP to promote responsible consumption and environmental stewardship. BOPP supports green consumption.