PET is also abbreviated PETE. It stands for polyethylene terephthalate. The chemical name of PET is polyester. It is a clear, sturdy, and lightweight plastic film. It is widely used for packaging foods and beverages, particularly convenience-sized soft drinks, water, and juices.

PET plastic film usually refers to BOPET due to its numerous applications. BOPET is abbreviated for Biaxially-oriented polyethylene terephthalate. BOPET or Biaxially-oriented polyethylene terephthalate film is a polyester film. It is manufactured by stretching the polyethylene terephthalate.

This film is used for its superior tensile strength, dimensional and chemical stability, reflectivity, electrical insulation, transparency, and aroma/gas barrier properties. Many polyester film manufacturers offer BOPET and other polyester films under notable brand names.

In the US and UK, the most famous trade names are Melinex, Mylar, and Hostaphan. Some companies also offer colored polyester film like:

- Black Polyester Film

- White Polyester Film

- Blue Polyester Film

BOPET Film

What Are Polyester Film Properties?

The demand for PET has been raised due to its unique properties.

Polyester Film Properties:

- Polyethylene terephthalate is a high-performance, crystal clear plastic film manufactured from ethylene glycol and dimethyl terephthalate.

- Compared to other ordinary plastic films, the polyester film has superior tensile strength, outstanding dimensional stability, and little moisture absorption.

- This film maintains its physical properties at a pretty wide temperature range.

- PET film also has excellent UV resistance, exceptional electrical properties, first-class optical clarity, high gloss, and excellent gas barrier.

- It is a perfect film for high-quality printing and lamination. It is also a good option for high-performance plastic sheets and films.

- PET has a comparatively high melting point, making it appropriate for applications that need sterilization at high temperatures.

PET Film Market Trends

The Global “PET Film Market” is projected to rise at a high CAGR of 5.3% during the forecasting period (2021-2028). The PET Film market research report gives the latest industry data and future industry trends to recognize the products and customers driving revenue profitability and growth.

The report comprises the forecasts, investigation, and discussion of significant industry trends, market share estimates, market size, and profiles of the leading industry players. The final report prepared in 2021-22 also added the investigation of the impact of COVID-19 on this industry.

Since the COVID-19 virus outburst in 2019, the infection has spread to approximately 100 countries worldwide, with the WHO stating it a public health tragedy. The global effects of corona virus 2019 are already being realized; this disease has considerably affected the Packaging PET Film market in 2021. To deal with this problem, Corona Treated Polyester Film was prepared.

This report entails Product Segment Analysis, Market Dynamics, Segmentation Analysis, and Geographical Analysis.

Global PET Film Market: Product Segment Analysis

- BOPET (Biaxially-oriented polyethylene terephthalate) A-PET (Amorphous-polyethylene terephthalate)

- CPET (Crystalline Polyethylene Terephthalate)

Market Dynamics

The increasing demand for flexible packaging mainly drives the global PET Film Market. The dynamic force for flexible packaging is the rise in demand for suitable packaging desired in the food and beverages and pharmaceutical industries.

The other driving factor for the escalation of the PET film market is the increasing demand for the electronics devices market like LCDs, mobile, and others.

The PET film is used in the panel’s display of these electronic devices, which certainly drives the PET films market. Though, because of the instability in crude oil prices, PET resins’ raw material deters the market of PET film.

Segmentation Analysis

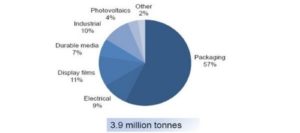

According to the application category, the global market of PET Film is segmented into:

- Flexible packaging

- Food contact applications

- Solar, marine, and aviation applications

- Covering over the paper

- Insulating material

- Electronic and acoustic applications

Among these segments, flexible packaging and food contact applications have high dominance. Due to PET film’s characteristic of having a low odor, high chemical resistance, and inertness is appropriate for packaging applications underneath FDA regulations.

First Grade and Qualified Grades are followed here.

PET Film Application Analysis

Geographical Analysis

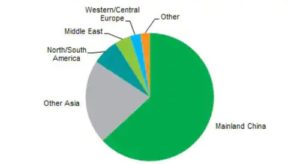

The global PET Film Market is segmented geographically into

- North America

- Asia-Pacific (APAC)

- Europe

- South America

- The Middle East and Africa (MEA)

Usage of PET film in the panel displays in electronics devices like LCD, mobile, and others has made APAC clutch most of the market share.

Though, North America is later than APAC in terms of market share of PET Film Market, followed by Europe. A developing nation like China and India has elevated demands for the PET Film market.

Geographical Analysis

What Are the Applications of BOPET Film?

BOPET film is frequently an outstanding option for more challenging use in food and nonfood-film applications.

It is highly recommended to use PET Film for Food Packaging. This film is available in various thicknesses, types, widths with properties customized to fulfill specific necessities of particular end users.

Due to outstanding water and moisture barrier properties, the plastic bottles manufactured from PET are extensively utilized for mineral water and carbonated soft drinks.

The significant uses of PET film include:

- Microwave and medical packaging

- Food packaging applications

- Plastic wrap

- Tape backing

- Printed films

- Plastic cards

- Protective coatings like solar and safety window films

- Release films

- Transformer insulation films

- Flexible printed circuits

- Tape applications

- Formation of packaging trays and blisters

- Formation of mesh fabrics for screen-printing, filter for oil and sand filtration, bracing wires for agricultural applications (greenhouses, etc.), filter cloth, woven/knitting belt

PET Film as Aroma Barrier Film

This film is also an aroma barrier film for coffee and tobacco packaging. This kind of film is sometimes metalized through vapor deposition of metals to advance the barrier properties of film against oxygen, aroma loss, and water vapor.

PET Film in Textile Industry

PET film offers a wide range of applications in the textile industry. Polyester fabrics are sturdy elastic and provide the further advantage of less shrinkage and wrinkles over cotton.

The materials made from polyester are lightweight, drag-resistant, reduced-wind, and more resistant to tears.

PET Film in the Electrical and Electronics Industry

It is one of the most commonly used films in the electrical industry.

Why?

Because, it has first-class electrical insulating properties, high structural and dimensional stability.

PET Film in the Automotive Industry

PET film is effectively being utilized in many applications in the automotive industry. This film is presently being used in the following applications:

- Wiper arm and gear housings

- Headlamp retainer

- Engine cover

- Connector housings

PET Film Applications

If you are looking for a plastic film perfect for flexible packaging and food packaging, PET film is your ultimate partner. The market demand for PET film is rising due to its remarkable properties. PET film is used in various applications. In China, the best Polyester film supplier is Kingchuan Company. Our company offers PET film of different types, widths, and thicknesses for end users.