An Introduction to Overwrapping

Overwrapping is also known as tuck and fold packaging. It is a fully enclosed wrap using heat sealable films and can be filled and sealed either horizontally or vertically. Overwrapping fulfills three different functions to keep loose products collated together, including:

- Primary packaging

- Secondary packaging

- Transit packaging

The main purposes of overwrapping are to advance the shelf life of the product and deliver product protection. In addition to these benefits, overwrapping can also offer tamper evidence, product shelf appeal, cost reduction, pack promotion, multi-packing convenience, and easy opening.

Overwrapping not only improves product presentation but also preserves freshness and enhances shelf life. The wrapping process requires low energy and low material costs. Its versatility and flexibility make overwrapping an attractive application for a wide range of industries.

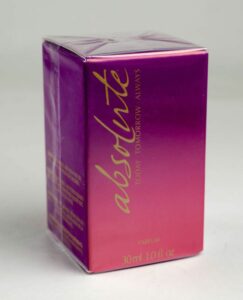

Overwrapping is the preferred packaging method for wrapping strong-scented products such as cigarettes, cannabis, cookies, or perfumes particularly.

BOPP Glossy Film for Overwrap

Types of Overwraps

There are four main types of overwraps based on the material used for this purpose.

1. Film Wrap

This overwrap is composed of plastic films, particularly:

- Polypropylene or BOPP Glossy film

- Polyethylene

These films can be wrapped around an item and attached with adhesive, PSA tape, or heat seals. Sometimes the film is in the shape of a plastic bag that is sealed around the object.

2. Shrink Wrap

Shrink wrap is prepared with polymer plastic film. When heat is applied, it shrinks firmly over whatever it is covering. A heat gun (electric or gas) can be used to apply heat to this wrap by hand. Heat can also be applied by passing the product and film through a heat tunnel.

3. Decorative Wrap

It is also known as gift wrap. These wraps can be either solely for visual appeal (decoration) or be protective in nature. They mainly contain a decorative element such as a printed design.

4. Paper Wrap

Kraft paper and various other papers can be used to overwrap items or a package. Some papers offer abrasion protection for packaged items.

Sealing can be achieved by applying adhesives, tapes, heat seals, etc. Some paper wraps provide grease resistance. They are usually saturated with volatile corrosion inhibitors.

How to Choose the Right Overwrapping Film?

Now that you know the various types of overwraps, it is time to select the one that fits your business better. If you aren’t sure how to narrow down your choice, start by considering the following factors.

1. Your Budget

The first thing you have to think about is your budget.

Shrink wraps cost more than BOPP glossy films overwrap. If you don’t have a lot of wiggle room in your budget, you might want to overwrap as many items as possible.

Your preference must be BOPP glossy films for overwrapping these items. This film is not only cost-friendly, but it also provides better barrier protection than paper wraps or shrinks wraps.

2. What You’re Wrapping

You might not be able to overwrap your products based on their size and shape. In this situation, you’re better off using BOPP glossy films.

BOPP overwrap film can be used for wrapping almost every sized product. This film will make your overwrap look nice on a product by perfectly fitting it in.

3. The Final Look

Overwrap can give your products a more professional look most of the time. This can be better for business.

But that doesn’t mean you should pick overwrap for products it doesn’t fit. Again, you might make the packaging look worse if you try this.

For the better appearance of your product, you can choose BOPP glossy film. Shrink wrap may have rough seems, but it will work much better for a lot of products.

Overwrapping on Food Packages

What Is BOPP Glossy Overwrap Film?

Biaxially oriented polypropylene Glossy film is a kind of flexible packaging film.

Biaxially oriented polypropylene overwrap film is stretched in a machine and transverse direction. This results in a molecular chain orientation in both directions.

How It Is Manufactured?

BOPP Glossy film is prepared by following two methods:

1. Tubular Production Process

This type of overwrapping film can be created via a tubular production process. A tube-shaped film bubble is inflated and heated to its softening point (this is different from the melting point) and is stretched with machinery. The film stretches between 300% – 400%. This stretching ability allows it to work perfectly for overwrapping multiple items.

2. Tenter-Frame Process

BOPP glossy film can also be stretched by a procedure known as tenter-frame film manufacturing. With this method, the polymers are extruded onto a cooled cast roll (also known as a base sheet) and drawn along the machine’s direction.

Tenter-frame film manufacturing uses numerous sets of rolls to create this film. The tenter-frame process generally stretches the film 4.5:1 in the machine direction and 8.0:1 in the transverse direction. These ratios are fully adjustable.

The tenter-frame procedure is more common as compared to the tubular variant. It generates a highly glossy, transparent film. Biaxial orientation increases strength, superior stiffness, enhanced transparency, and high resistance to oil and grease.

Benefits of BOPP Glossy Overwrap Film Packaging

In addition to its ability to be used as a combiner, which makes it perfect for applications like large packages of bottled beverages, overwrapping can significantly boost traditional forms of packaging.

Sometimes, it can even eradicate the need for traditional packaging films altogether. Through the use of flexible materials and custom sealing, BOPP gloss film overwrapping allows for the following benefits:

1. Tamper Protection

Overwrapping offers excellent tamper protection. Overwrap needs to be broken in order to extract the product inside, and it is difficult to reseal, making it easy to spot if a product has been tampered with.

Applying a seal almost impossible to duplicate once broken will guard against contamination and quickly alert workers and customers to unsafe packages.

2. Aroma Control

Overwrapping can be used to generate a near-hermetic seal to prevent cross-contamination and the release of odor effectively. Overwrap has the ability to lock in scents, avoiding cross-contamination of scents from other products.

3. Extended Shelf Life

Overwrapping extends the shelf life of products by preventing bacteria transfer. BOPP glossy film overwrap protects the contents from environmental hazards and airborne microbes.

BOPP Glossy film overwraps keep the content from dirt for exterior context. By enhancing the shelf life of products, BOPP overwrap saves companies both time and money.

4. Reduced Costs

By eliminating the need for more elaborate designs or heavier packaging materials, BOPP overwrapping results in lower costs and simpler labor operations.

5. Ease of Use

Easy-open or resealable options using design elements such as tear tape allow for simple, convenient user access.

6. Custom Promotional Features

Overwrapping provides opportunities for enhanced hand-wrapped or high-end design effects, as well as product bundling and the addition of eye-catching marketing messages.

7. Eco-Friendliness

BOPP film Overwrapping utilizes less packing material than traditional solutions. It is available in biodegradable and eco-friendly forms.

Compared to shrink wrapping and other wrapping styles, BOPP film overwrapping provides a cleaner, sleeker appearance and a more professional finish.

8. Versatility

BOPP glossy film offers secondary packaging and can also be used for primary packaging of various products like soap. It is also applicable for multipack overwrapping in order to bundle several products together.

Overwrapped Perfume

Applications of BOPP Glossy Overwrapping Film

BOPP glossy over wraps has more Impact resistance, and flex crack resistance than shrink film wraps. Moreover, BOPP film also boasts increased barrier properties to vapor and oxygen.

Due to these properties, BOPP film is used in various applications. Biaxially oriented polypropylene overwrap films are most commonly used for food packaging.

They are fast replacing cellophane for applications including snack food and tobacco packaging due to their superior properties and lower cost. BOPP overwraps obscure a package for distribution, sale, or gifting.

Clear Heat Sealing BOPP Glossy Films for Cigarette Boxes

Businesses that usually use BOPP overwrap films include:

- Food manufacturing and distribution companies

- Tobacco companies

- Supermarkets

- Consumer goods manufacturing companies

- You can see BOPP overwraps at your local supermarkets, retail food stores, and gas stations.