Healthcare infection prevention is vital. Healthcare-associated infections (HAIs) threaten patients, workers, and systems. Some strategies to mitigate these risks include using advanced materials. Due to its protection, barrier, and endurance, metalized biaxially oriented polyethylene terephthalate (BOPET) films from China Metalized Bopet film manufacturers are essential to surgical drapes and gowns for infection control. The significance, characteristics, manufacturing technique, and surgical drapes and gown usage of metalized BOPET films are examined in this comprehensive review.

Health-related infections

Hospitalized people get nosocomial infections. These infections may include surgical site, urinary tract, bloodstream, or respiratory tract bacteria, viruses, fungi, or parasites. HAIs occur in 1 in 31 US hospitalized patients daily, according to the CDC.

Metallization protects BOPET coatings against moisture, gases, and odors. Pharmaceutical packaging needs this barrier to protect drugs from environmental factors that affect efficacy. Metalized BOPET coatings shield fragile drugs from UV and light.

Operation gowns and drapes reduce infection

Drapes and gowns isolate the operating room, staff, and environment, reducing HAIs. These protective garments and barriers prevent pathogens from spreading by direct contact, airborne particles, or fluid splatter during surgery and other invasive procedures. Safe surgical drapes and gowns prevent hospital infections and enhance results.

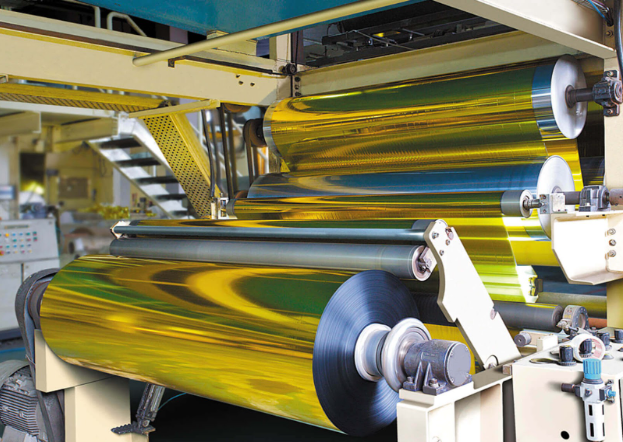

Metalized BOPET Film Production and Description

These advanced metalized biaxially oriented polyethylene terephthalate (BOPET) sheets from China Metalized Bopet film suppliers are perfect for surgical gowns and drapes. Metallization works well with strong, flexible, transparent, barrier polyester film BOPET.

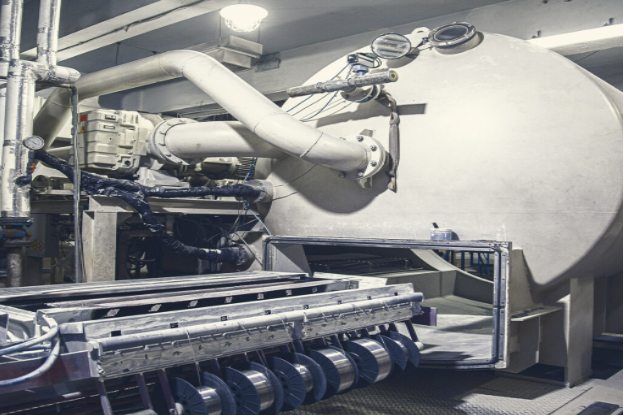

Making metalized BOPET films begins with the biaxial extrusion of PET pellets into a thin film. This gives the film mechanical strength, dimensional stability, and barrier properties. A light aluminum coating is vacuum-deposited on the BOPET film to metalize it. The metalized layer enhances the film’s microbiological barrier while maintaining its surgical flexibility and drapability.

Metal BOPET Films in Surgical Drapes and Gowns

Metallic BOPET films in surgical drapes and gowns prevent infection, last, and save money. Barrier systems that separate the operating area, limit microbiological contamination, and preserve sterility need these films. Surgical drapes and gowns employ metallic BOPET films for:

- Barrier Protection: Metalized BOPET films restrict microbial penetration from the environment to the surgical site. The metalized layer protects the film against airborne particles, fluid spatter, and microbiological colonization.

- Durability and Tear Resistance: BOPET films can withstand surgical mechanical stresses due to their strength and tear resistance. Metalization strengthens the film and decreases barrier tears.

- Flexibility and Drapability: Metalized BOPET films conform to body and surgical instrument shapes without restricting mobility. Doctors require this flexibility during surgery to cover pro and tect and maintain precision and control.

- Sterility: Metalized BOPET films from China Bopet film manufacturers keep microbes from the operating room. The metalized coating prevents operation site infections by blocking bacteria, particles, and liquids.

- Cost-Effectiveness: Metalized BOPET films outperform surgical drapes and gowns at lower cost. Durable and reusable BOPET films reduce healthcare institution procurement expenses and replacement frequency.

Uses of Pharmaceutical Packaging:

Flexibility and performance make metalized BOPET films popular in pharmaceutical packaging. Common uses:

- Blister Packaging: Metalized BOPET sheets resist moisture, oxygen, and light in blister packs’ webs or lids. Tamper-resistant blister packs and unit dosage packaging ensure product purity and dosing.

- Sachets and Pouches: Flexible metalized BOPET film sachets and pouches package powders, granules, and liquids. These films’ outstanding barrier properties keep pharmaceuticals fresh throughout storage and delivery.

- Strip Packaging: Metalized BOPET films from China Bopet film suppliers package tablets and capsules. These strips avoid contamination, modify dosage, and are easy to use.

- Overwraps: Jars, flasks, and vials are enveloped in metalized BOPET coverings. They keep medicines dry and intact.

- Pharmaceutical Inserts and Labels: BOPET films that have been metalized are used for these purposes. Metallic labels appear better and withstand moisture and wear.

Metalized BOPET Film Advantages:

Pharmaceutical packaging using metalized BOPET sheets has several benefits:

- Better Barrier Properties: Metallization protects BOPET films from moisture, oxygen, and light. This extends drug potency and shelf life.

- Cost-Effectiveness: Pharmaceutical packaging using metalized BOPET sheets is cheaper than aluminum foil. They provide comparable barrier effectiveness at a lower cost, attractive to packing efficiency businesses.

- Packaging flexibility: Metalized BOPET sheets exist in various thicknesses, widths, and finishes. Pharmaceutical packaging may be customized to meet application needs.

- Sustainability: BOPET films are recyclable and lightweight. Film metallization reduces transportation and disposal emissions by adding minimal weight.

- Visual Appeal: The metalized surface of BOPET sheets elevates pharmaceutical packaging. This may distinguish pharmaceutical brands and consumer perception in a competitive market.

Conclusion

For infection prevention, surgery drapes and gowns require metalized BOPET films. These innovative materials protect, barrier, endure, and save money while remaining sterile. Hospitals can enhance infection control, healthcare-associated infections, and patient outcomes using metalized BOPET films. Pharmaceuticals must be shielded against moisture, air, and light for product integrity and patient safety. Metalized BOPET sheets will suit pharmaceutical packaging sustainability needs. Technological advances in metalized BOPET films will enhance hospital infection control and operating safety.