The flexible packaging market is becoming intense, with packaging laminates contributing a 6.1% share of the global packaging films market. Currently, food & beverage, and pharmaceutical manufacturers around the globe have adopted high-quality packaging solutions.

These solutions have driven the sales of lamination packaging films. Let’s find out the process of lamination in flexible packaging.

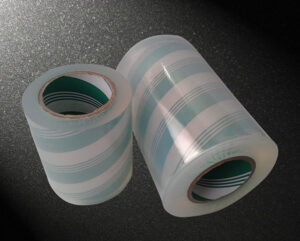

BOPP Cold Laminating Film

What Is the Process of Flexible Packaging Laminates?

Flexible packaging is a non-rigid material that is used as a means of different packaging products. At the same time, the process in which two or more flexible packaging webs tend to join together using a bonding agent is called laminating.

Flexible packaging provides more customizable and economical options. The substrate making the webs can consist of films, papers, and aluminum foils. The lamination process involves adhesive applied to the substrate that is comparatively less absorbent.

The second web is pressed against the first to produce two-layered or 2ply laminate.

BOPP Films

Over the last few years, the demand for BOPP film has increased to 3.5% per annum. The need for flexible packaging has given a boost to BOPP film.

BOPP (Biaxially Oriented Polypropylene Polymer) films are the most advanced, cost-effective, and multi-functional laminating solutions. BOPP films are prepared using high-standard quality and customizable designs to keep the products for a more extended period.

Being an effective moisture barrier, BOPP laminates have enhanced the shelf life of various products. Let’s find out about this rising market’s packaging solution.

BOPP Laminates

Types of BOPP Films

BOPP films are available in different types. Flexible packaging needs to be as customizable as the name suggests. Therefore, BOPP films play a significant role in various fields by offering a number of its types. These types include:

· BOPP Holographic Film

It is a smooth and cleared holographic surface film that provides superior bonding strength. These are available in transparent and opaque both.

Usage:

You can use BOPP holographic film in the same way as a cold laminating film. A transparent holographic film gives strength and also enhances the visual appeal of the product. This type of lamination is mostly used to enhance brand packaging.

BOPP Transparent Holographic Film for Cold Lamination

· Printable BOPP Film

Printable BOPP film (white) has excellent gloss and high transparency. BOPP films are known for their excellent printability. Therefore this film is an ideal solution when it comes to advertising or decorating a product.

Usage:

You can use both side treated glossy or matte BOPP films for this purpose. Printed side remains at the outer side while the inner side is joined (to the other film) with an adhesive.

Printed BOPP Laminated Bags

· BOPP Matt Film

BOPP matt film generally has a matte effect on one side and is transparent on the other. But it can be matt from both sides. It has excellent machinability and is ideal for cold lamination. With the eco-friendly film property, it is also significantly water and pollution-resistant.

Usage:

This BOPP matt film is mainly used for flower packaging, reverse printing, lamination, textbook covering, and foodstuff packaging for flexible packaging.

Matte BOPP Lamination Film

· Heat Sealable BOPP Film

Heat sealable BOPP film is stretchable, printable, and ideal for thermal lamination. It is a multi-layered film in which the first layer is a protective coating for the core. Then the core layer is BOPP film, and the innermost layer is heat-sensitive.

Usage:

Heat sealable BOPP film comes with a high-intensity seal to provide a secure and tight bond for flexible packaging that includes bakery items, confectionaries, and biscuit wraps.

· BOPP Pearlized Film

This film is a pearl-like white film that is opaque. It is the most in-demand film because the white surface provides excellent print adhesion.

Usage:

BOPP pearlized film laminates ice creams, candies, labels, drugs, and cosmetics. This film protects the products from sunlight, moisture, bacteria, and odor. It has low density, good machinability, and is antistatic.

Therefore you can easily use this film in printing and laminating machines. Also, due to its glossy and beautifully printing appearance, retailers prefer to have this film.

· BOPP Glossy Film

This glossy film is available with different thicknesses, widths, and properties to laminate. BOPP glossy film is amazingly eco-friendly because, upon sun exposure, it doesn’t emit toxic materials. Thus, this film is the best to laminate food products. You can get BOPP glossy film in different types like matte, printable, tape-grade, and pearlized.

There are more than 1000 variants of BOPP gloss films. This film is in high demand because of its durability, strength, recyclability, and versatility.

Usage:

This film is ideal for cold lamination as it shows high adhesion strength with water-based, solvent-based, UV, or hot-melt adhesives. These laminates are ideal for hygiene and personal care products.

Glossy BOPP Laminating Film

Advantages of BOPP Films for Lamination

The expanding flexible packaging industry has driven the increasing demand for BOPP films for lamination. BOPP films offer many advantages which are:

· Product Quality

Incredible strength, broad sealing window, and excellent machinability help the food industry protect quality. The moisture barrier by the BOPP film is an incredible benefit that keeps the product alive.

· Extended Shelf Life

BOPP films provide excellent oxygen and moisture barrier that helps the product stay fresh, extending the product’s shelf life. The food and beverage industry uses BOPP film laminates religiously to avoid food wastage and extend food life.

· Sustainability

BOPP film has fewer carbon footprints than other films; therefore, it is eco-friendly. Food packaging requires different variants to keep them safe in flexible packaging. BOPP films come in handy because of their low melting point.

· Density

It is lightweight and thin; thus, you can easily handle it. With the low-density property, BOPP film is less consumed in product packaging. The low-density material allows BOPP film to be used among different packaging products, like food, medicines, candies, chewing gum, tea, and all other flexible packaging items.

· Graphics

BOPP films have excellent transparency, allowing for the product’s quality aesthetic appeal. You can have half print, a white opaque film with a glossy side, high opacity, and multi-colored prints in high-quality graphics for the perfect product packaging.

Also, there are other ways to get the aesthetic appeal to another level in BOPP films. You can also foil stamp, UV spot coat, and emboss on the product packaging.

BOPP Laminates for Flexible Packaging

Application of BOPP Film Laminates in Flexible Packaging

BOPP film is used in several industries with its vast range of applications. The reasonable economics, moisture resistance, optical clarity, and high tensile strength make the BOPP film usage in the following areas:

- Food and packaging

- Medical packaging

- Personal care product packaging

- Labeling purposes

- Decorative purposes

- Tobacco lamination

- Others

BOPP Laminated PP Woven Bag for Fertilizers

Why Choose BOPP Film for Lamination?

· Recyclable and Eco-Friendly

BOPP film is non-toxic and doesn’t keep any allergens to keep the environment clean and safe. BOPP film is reusable and also recyclable.

It retains its value and properties after recycling. It helps the companies to decrease their carbon footprints by recycling the film and eliminating waste. It is one of the main reasons to select this film for lamination.

· Exceptional Mechanical Properties

BOPP films have exceptional mechanical properties that they can customize in various forms. The moisture durability, sealing properties, and superior characteristics make it one of the most demanding laminates.

· Flexible and Versatile Properties

BOPP film is versatile, as it can provide high transparency and an exceptional gloss finish. This film is flexible enough to resist wrinkles and shrinkage. The elastic property of this film makes it perfect for lamination in various industries applications.

· Durability

BOPP film can keep the products safe even during wet weather and transportation. Its thin and lightweight properties don’t have any effect on its performance. Therefore, the lamination doesn’t damage and remains durable.