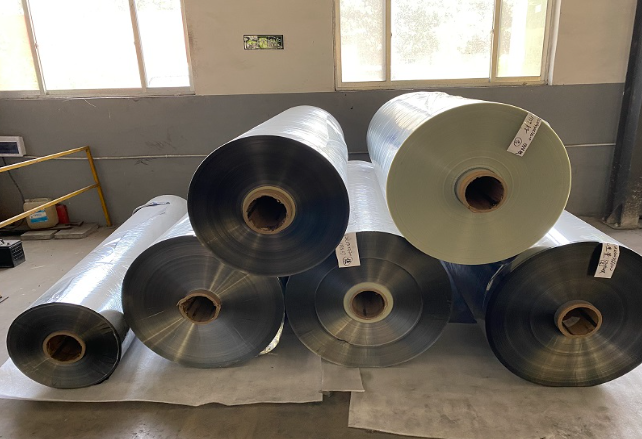

Biaxially Oriented Polyethylene Terephthalate (BOPET) sheet from China Bopet film manufacturer’s electrical insulation is versatile and widely used. Its superior electrical insulation is used in electronics and power transmission. This extensive study covers the BOPET film’s structure, manufacture, electrical insulation, and performance.

Manufacturing and Structure

Polyester film BOPET is PET. Its biaxial production orientation stretches the film in the machine direction (MD) and transverse direction, giving it remarkable properties. Biaxial polymer chains provide the film strength, clarity, and dimensional stability.

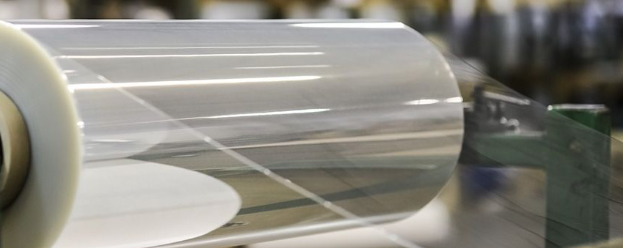

Extruded PET resin pellets are shaped into thick sheets using a flat die. Heated rollers stretch this sheet, biaxially in MD and TD. Stretching aligns molecules into a crystalline structure.

Heat-setting the film reduces internal tensions and locks molecular orientation. Corona or plasma discharge improves printability and adherence.

Electrical Insulation Results

The molecular structure of BOPET film from China Bopet film suppliers gives it high dielectric strength, low dielectric constant, and excellent electrical breakdown resistance. Its qualities make BOPET film appropriate for high-voltage and electrical stress insulation.

A material’s dielectric strength is its maximal electric field without breaking. Because of its hundreds of V/mil dielectric strength, BOPET film is suited for high-voltage capacitors, transformers, and electrical cable insulation.

Due to its low dielectric constant, BOPET film stores electrical energy better than other materials in an electric field. High-frequency applications like flexible PCBs and EMI shielding benefit from this, which lowers signal loss and distortion.

Due to its thermal resilience, BOPET film remains electrically insulating at several temperatures. Thermal stability ensures the reliability of temperature-changing automotive electronics, aircraft systems, and power distribution equipment.

Electrical Insulation Systems

Numerous mechanisms give BOPET film good electrical insulation:

- Low Dielectric Constant (ε): BOPET film from China Bopp film manufacturers holds charge without conducting current with a dielectric constant around 3.0. The low dielectric constant is attributed to biaxial molecular alignment decreasing dipole interactions.

- High Dielectric Strength: BOPET film can exceed 200 kV/mm. This property defines the material’s maximum electric field without breakdown. The film’s homogenous molecular orientation and lack of defects increase its dielectric strength.

- Smoothness: BOPET film’s smooth surface prevents partial discharges and corona, which can cause electrical failure. Corona discharge enhances film smoothness and electrical performance.

- Thermal Stability: BOPET film insulates electrically at several temperatures. Applications with fluctuating or high temperatures require this stability.

Performance traits

The electrical insulation efficacy of BOPET film varies on thickness, temperature, humidity, and frequency. Important performance traits:

- Thickness: Thinner BOPET films have higher capacitance per unit area, making them suitable for compact and flexible applications. However, thicker coatings enhance electrical insulation and mechanical strength.

- Temperature Resistance: Grade and application determine BOPET film’s temperature resistance from -70°C to 150°C. This makes it suitable for automotive, aerospace, and electronics.

- Humidity Resistance: BOPET film’s low water absorption and moisture resistance make it electrically stable in high humidity. This feature makes outside and damp performance reliable.

- Frequency Response: BOPET film electrical properties are steady from LF to RF and microwave frequencies. It suits applications requiring steady performance in various electrical circumstances.

- Corona Resistance: BOPET material resists corona discharge, which causes localized electrical breakdown in strong electric fields. Its smooth surface and uniform chemical structure prevent corona-induced degradation.

- Mechanical Strength: Due to its tensile strength and tear resistance, BOPET film can withstand mechanical stress and deformation without damaging electrical insulation. This material’s mechanical resilience makes it perfect for flexible packaging, protective films, and industrial laminates.

- Chemical Resistance: BOPET film resists oils, solvents, and acids. The chemical resistance benefits chemical processing industries, automotive components, and medical devices with high corrosion.

- Dimensional Stability: BOPET film resists environmental shrinkage, expansion, and distortion. Printing, coating, and metallization require flawless registration; therefore, dimensional stability is crucial.

- Optical Clarity: BOPET film is transparent and transmits light without clouding. Its aesthetics benefit display windows, optical films, and electronic display coatings.

Applications

BOPET film’s electrical insulation and performance make it essential in many applications:

- Capacitors: BOPET film capacitors are reliable due to their high dielectric strength, low dielectric loss, and thermal and electrical stability. Its high dielectric strength, low dielectric constant, and thermal stability make it excellent for film and metalized capacitors.

- Insulating Tapes: BOPET film from China Bopp film suppliers is used for wiring and cable insulation. Its mechanical strength, temperature resistance, and electric insulation enable long-term durability under challenging environments. Cables, motors, generators, and transformers also use BOPET film insulation. Its superior electrical insulation makes equipment safe and efficient in high-voltage environments.

- Flexible Printed Circuits (FPCs): BOPET film makes lightweight, compact, and reliable electrical interconnects for smartphones, laptops, and wearable devices.

- Electrical Insulation Sleeving: BOPET film sleeves protect automotive, aircraft, and industrial wires, cables, and components. Abrasion, chemical, and environmental resistance are available.

- PV module backsheets: BOPET film insulates, protects, and lasts. Thermal stability and weather resistance extend solar installation life. BOPET film protects solar panel photovoltaic cells from moisture, dust, and mechanical damage; renewable energy solar modules last longer due to their longevity, weather resistance, and optical clarity.

- Flexible PCBs: BOPET film’s substrate acts as electrical insulation and mechanical support for circuit traces and components.Dynamic applications that require bendability and durability benefit from its flexibility, dimensional stability, and temperature resistance.

- Packaging: Flexible food, pharmaceutical, and industrial packaging uses BOPET film. Barrier, sealability, and printability safeguard numerous products while keeping vision and brand identity.

- Labels and Decals: BOPET film brands, signs, and identifies products. Its printing surface, dimensional stability, and adhesive compatibility make it ideal for high-quality graphics and text that must last and attach to various surfaces.

Conclusion

The apex of material development, BOPET film, has electrical insulation, mechanical strength, thermal stability, and adaptability. Its biaxially oriented structure, dielectric characteristics, and performance under diverse operating conditions make it crucial across sectors. As technology advances and demand for high-performance electrical insulating materials develops, BOPET film enables electrical and electronic systems to innovate and be reliable.